The hemp/cannabis biomass is frozen. This frozen plant material is size reduced using a shredder and fed into the extraction system.

This process converts the plant materials into cannabis miscella.

Through a pre cooler, the solvent is passed to the cryogenic extractor.

The pre programmed (HMI UNIT), starts the extraction process by starting the recirculation pump. The agitator runs at a specific interval in clockwise and anticlockwise directions. Once the extraction is complete, the agitator stops, the diversion valve opens, and the CBD rich miscella is pumped to a tank.

After complete draining of miscella, the fly bolts are removed and by hydraulic means, the bottom is opened and the spent biomass is discarded.

This Cannabis miscella is separated into liquid phase and solids phase in a Plate and Frame filter press/ zero hold up filter press. The solids are thrown and the cannabinoids rich liquid is processed in a distillation system. The miscella thus obtained is volume reduced by means of low temperature evaporation under vacuum. The product thus obtained is paste. Then the highly concentrated cannabinoid extract is dried in a vacuum tray drier.

Our cryogenic extraction process system is having the following work stations:

USP of our material preparation procedure for cryogenic process:

The filtration system is optional as we already have integrated filter in the extractor itself. We normally supply plate and frame filter press. The numbers of filter plates vary on the basis of the volume of miscella to be filtered. The filter plates can be PP or SS.

For small volume filtration, we supply zero hold up filter press.

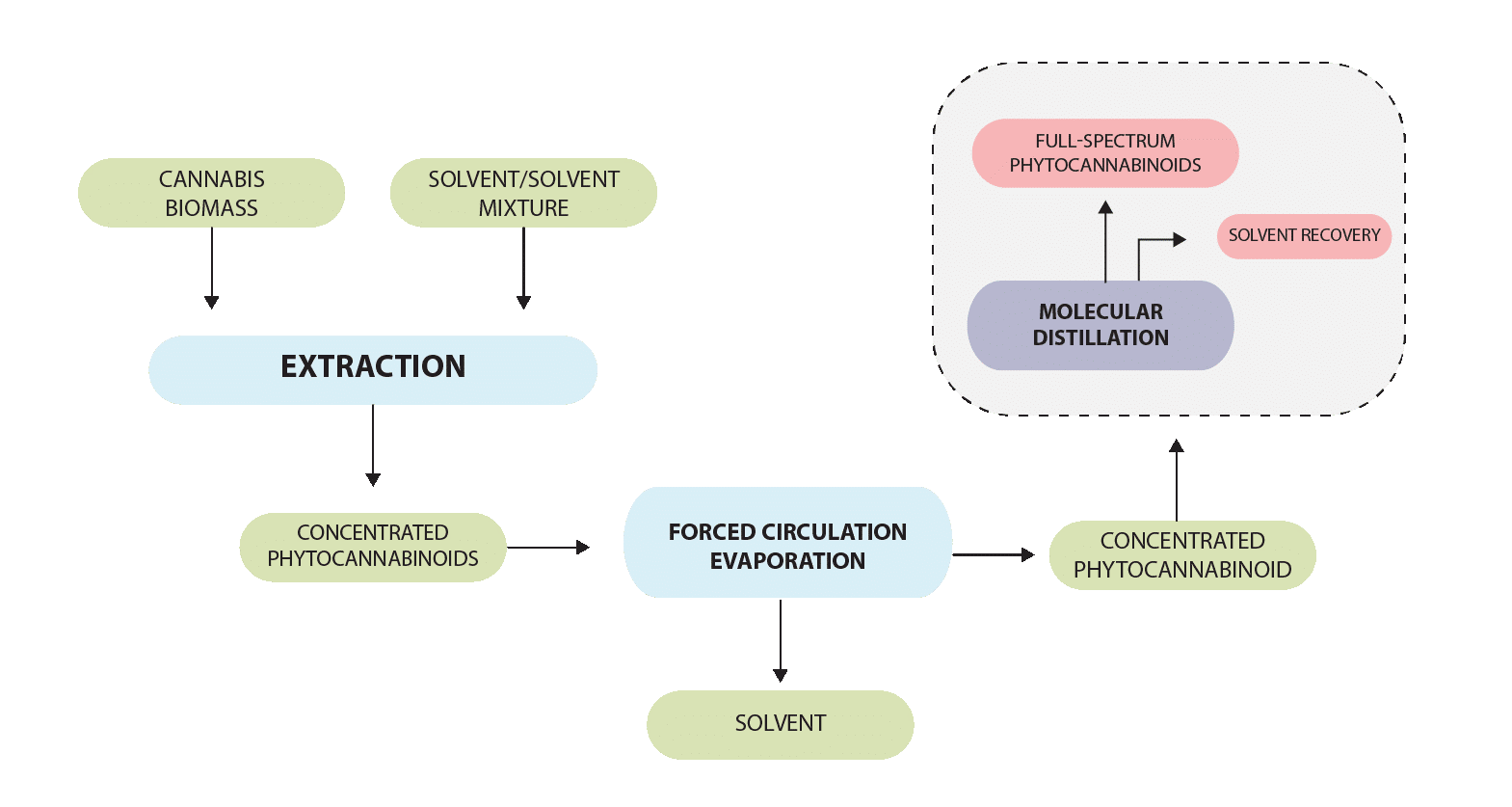

The miscella (oil and solvent) after the extraction of phytocannabinoids from solid-liquid extraction methods of dry cannabis biomass or hydrodynamic methods of extraction of phytocannabinoids from fresh cannabis biomass must be distilled and concentrated (solvent recovery), to get a solvent-free, highly concentrated full-spectrum extract. Also, the full-spectrum phytocannabinoids can be subjected to distillation to remove much of the tetrahydrocannabinol (THC) and produce a broad-spectrum distillate.

At Clean Green Biosystems, we have designed a PLC-SCADA-based method (Programmable Logic Controller-Supervisory Control and Data Acquisition) for separating molecules from cannabis, called Low Temperature Short – Contact Distillation Path, which combines forced circulation evaporation and molecular distillation. View More

Once the extraction is complete (whether solid-liquid or liquid-liquid extraction in case of patented hydrodynamic technology), the miscella (containing the extracted phytochemicals and solvent) is collected in a tank and is subsequently evaporated through a forced circulation evaporator and molecular distillation system. Depending upon the miscella volume that needs to be processed, single, double, or multistage systems may be employed.

The forced circulation evaporation system is composed of shell and tube heat exchangers, a flash evaporator, and primary and secondary condensers. The ASME-compliant shell and tube heat exchangers heat the miscella so that the vapour is created. The primary condenser distils the first-pass vapour whereas the secondary condenser further refines vapour from the primary condenser. This integration helps in efficient recovery of vapours. The forced circulation evaporation system removes around 75-80 % of the solvent from the miscella. The output of this evaporation process is concentrated miscella, which can be further purified using molecular distillation. View More

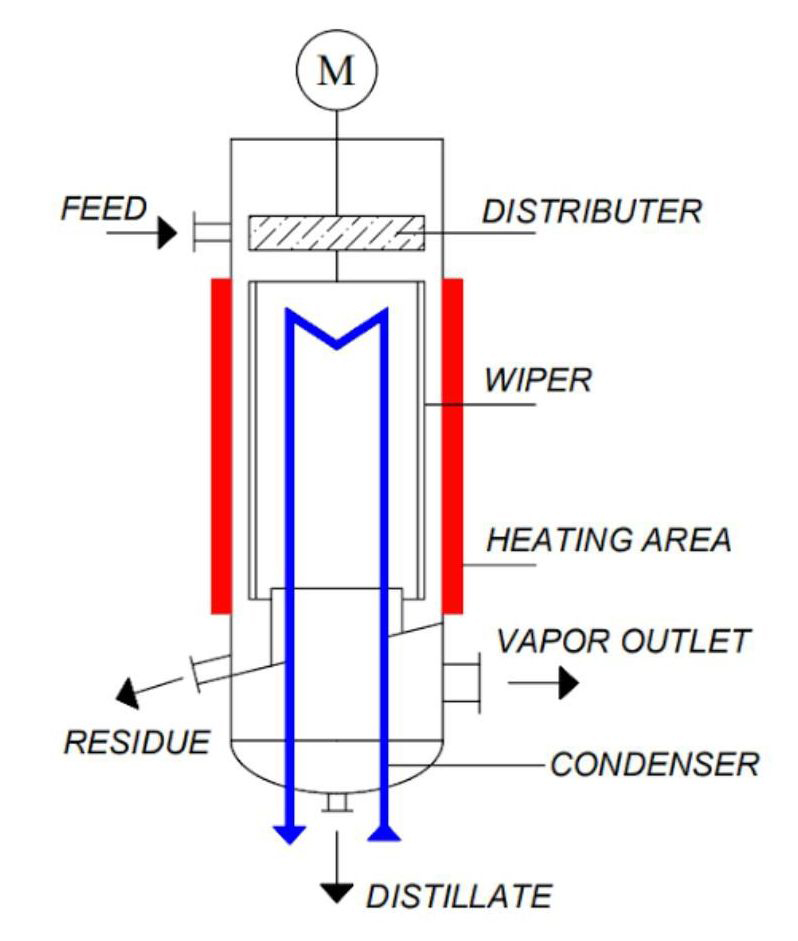

Thermally unstable compounds can be safely purified or separated by applying molecular distillation methods.

As Phytocannabinoids are higher molecular weight, thermo labile compounds, the application of high vacuum distillation methods, such as molecular distillation, are used to isolate/separate/purify components without thermally degrading them. A molecular distillation unit has a feed vessel that introduces miscella into the unit, whereupon the wipers spread an even coating as a thin film on the heated walls of the unit, thereby increasing the surface area. Specific and proprietary wipers can produce a thin layer of extract that’s 0.05 – 0.1 mm in thickness, significantly enhancing the evaporation surface area. The speed of the wiper blades’ rotation can be optimized and controlled to ensure uniform flow of the miscella for a rapid and efficient evaporation.

Molecular distillation uses short-path evaporators, and the distance (varies with flow and evaporation rates, but typically between 1 and 30 cm) between the evaporator and the condenser minimizes pressure drop. The distance between the heating and cooling surfaces is carefully designed to have a faster, rapid, and efficient separation of solvents from the miscella. The thermally labile molecules have short contact times with heat (may be as low as one millisecond), and thus, decomposition of the molecule(s) is kept to a minimum or does not occur at all. The evaporated solvent is condensed using chilled water, and the thick/concentrated miscella is expelled by the wipers. The solvent/solvent system is collected through an external vent condenser and can be used to extract further materials. The highly concentrated cannabis extract is collected for further processing or for direct use.

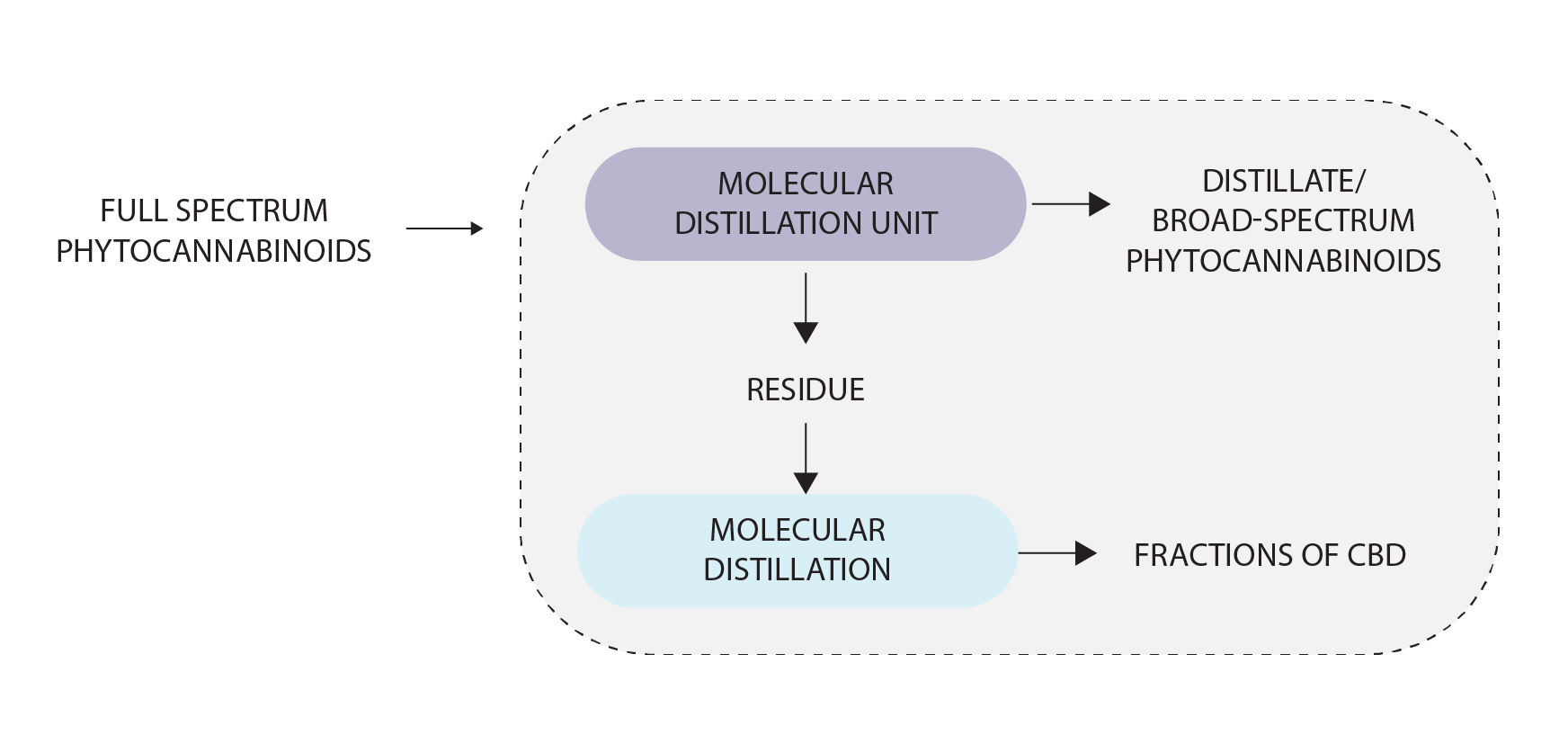

The resultant product can be further distilled to get THC-remediated, broad-spectrum product. Various fractions of the broad-spectrum phytocannabinoids can also be isolated using the molecular distillation system by adopting different standard operating procedures.

In sum, molecular distillation provides a way to retain molecular integrity and to purify thermally unstable molecules and related compounds having low volatility and elevated boiling points. The method uses low pressures (1-5 Pa, 0.01-0.05 mbar)..All process control systems like temperature control, flow control, vacuum control, and product viscosity are controlled by PLC-SCADA software.

Clean Green Biosystems offer Vacuum tray driers, rotacone driers, ribbon driers of various capacities. We supply suitable vacuum systems for the driers.

Tetrahydrocannabinol (THC) remediation is the removal of THC to the legalised level (0.2 to 0.3%) in any of the CBD products. All our systems are equipped and integrated with a THC remediation system which has a molecular distillation system, heat exchangers, condensers and chilling units.

Clean Green Biosystems equipments do the decarboxylation process considering the boiling points of converting the acidic forms of CBD to CBD. The solvents and its traces are completely removed from the CBD highly concentrated miscella in the VTD, and after completing it, the decarboxylation process starts in the VTD itself at specific temperatures with a progressive temperature increase which is controlled by PLC-SCADA based automation.

Clean Green Biosystems offer downstream processing systems to produce various fractions of CBD. The downstream processing equipments like column chromatography, ANFD, crystallizer, fractionation columns, washing columns, separating columns, pulverizers, mixers, blenders and rotary evaporators.

We support our clients with the operation manuals of the supplied plants, SOP’s and maintenance services. Also, we impart training of the technical staffs of our clients during and after the commissioning of the plants.

Clean Green Biosystems

Plot no. 160, Karpagam Nagar,

Thirumudivakkam, Chennai- 600 044

Dr. S. Prem Mathi Maran, Ph.D., D.Sc.,

Chief Executive Officer

Mobile: +(91)-80561 26827

Email: ceo@cleangreenbio.com | info@cleangreenbio.com